Sublimation Time And Temp Chart

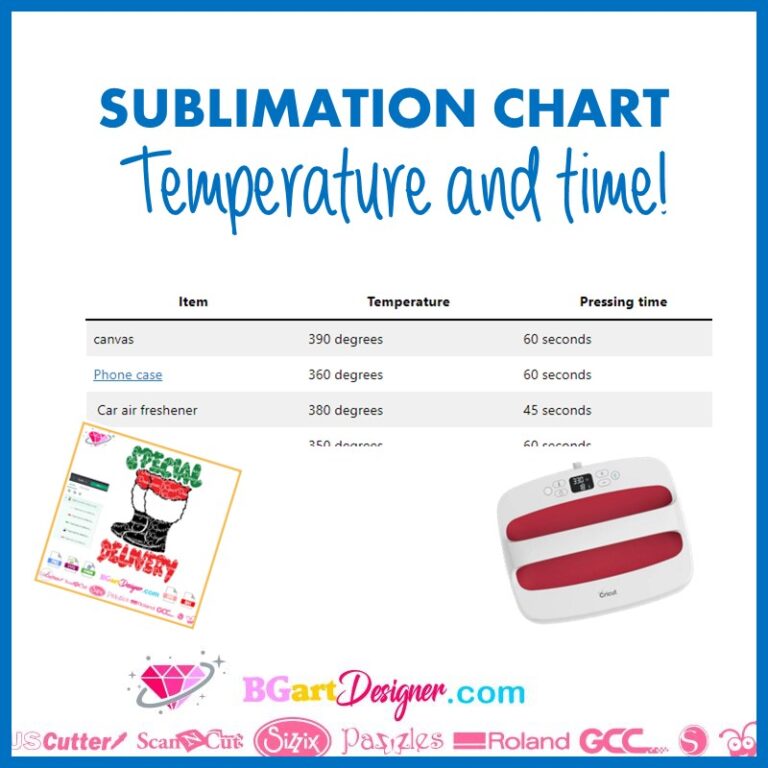

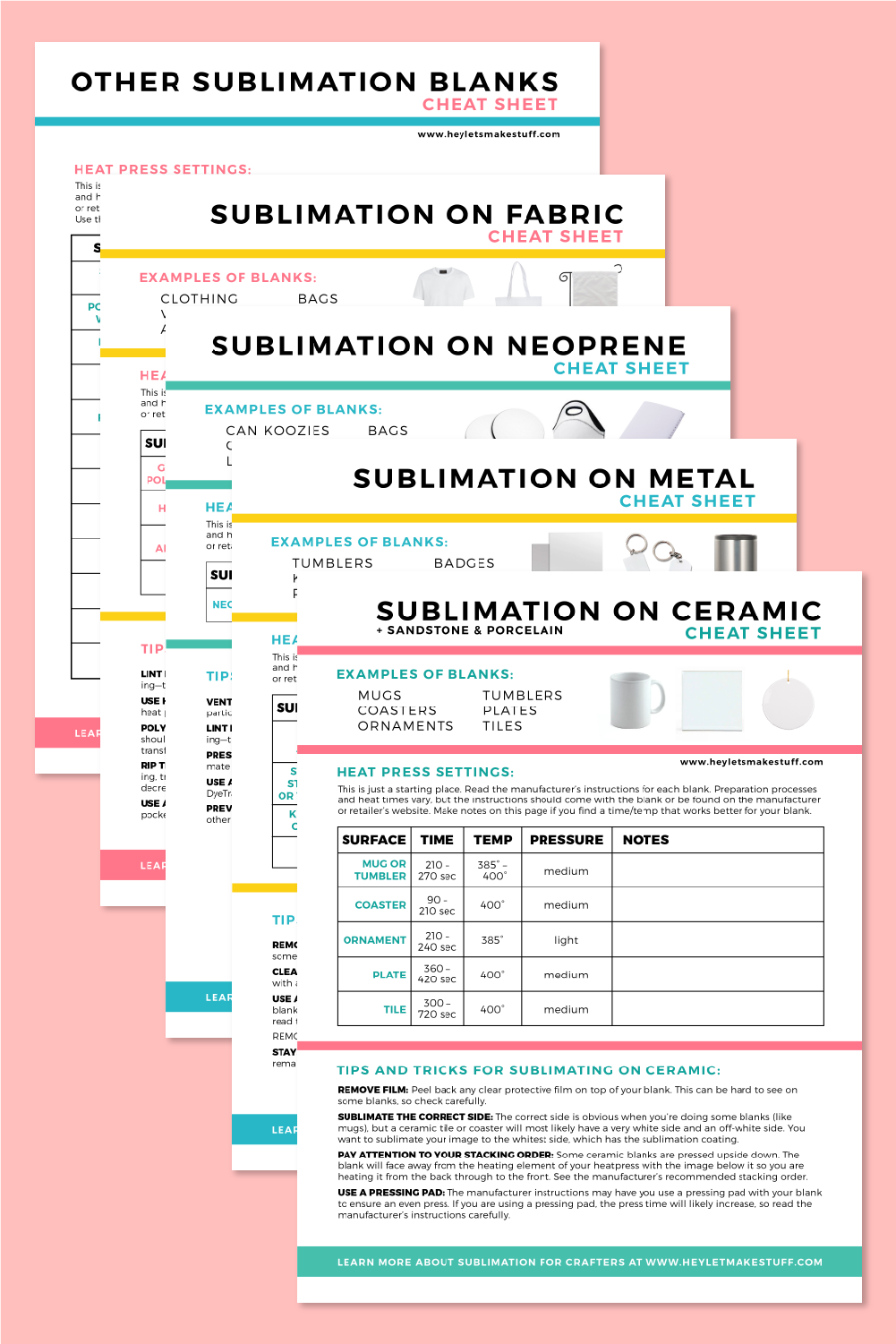

Sublimation Time And Temp Chart - The correct temperature will ideally let the ink bond with your substrate, reducing the chances of damage. Set the heat press to 380°f (193°c) for most substrates; The following chart should serve only as a starting place. This comprehensive guide covers the ideal settings to. Web getting the heat press time, temperature, and pressure parameters precisely right is crucial for ensuring a deep, lasting ink transfer that brings images to life. These sublimation cheat sheets give you the answers, plus offer tips and tricks for getting your sublimation transfer right the first time. Web a lower heat press temperature can seem like a safe starting point, but can produce light colors. What temperature do you sublimate 100% polyester? Web need a quick and easy way to know the time, temperature, and pressure settings for popular sublimation blanks? Web sublimation heat press settings. These sublimation cheat sheets give you the answers, plus offer tips and tricks for getting your sublimation transfer right the first time. Web this comprehensive time and temperature chart serves as a foundational resource for sublimation practitioners, offering precise recommendations for achieving optimal transfer results across a diverse range of substrates. Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following manufacturer guidelines, testing and practice! Your settings will define the durability of your product. The following chart should serve only as a starting place. Set the heat press to 380°f (193°c) for most substrates; Web a lower heat press temperature can seem like a safe starting point, but can produce light colors. The print may crack or peel off from the substrate without the perfect settings. The correct temperature will ideally let the ink bond with your substrate, reducing the chances of damage. The following chart should serve only as a starting place. Web refer to our sublimation heat press settings chart for information on press time for different substrates. Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following. Your settings will define the durability of your product. Adjust based on the specific material’s requirements. Web need a quick and easy way to know. The correct temperature will ideally let the ink bond with your substrate, reducing the chances of damage. This comprehensive guide covers the ideal settings to. Web need a quick and easy way to know the time, temperature, and pressure settings for popular sublimation blanks? Web refer to our sublimation heat press settings chart for information on press time for different. The correct temperature will ideally let the ink bond with your substrate, reducing the chances of damage. What temperature do you sublimate 100% polyester? So let’s talk about common sublimation heat press settings and how to determine times, temperatures, and pressures for different materials. The following chart should serve only as a starting place. Set the heat press to 380°f. Web refer to our sublimation heat press settings chart for information on press time for different substrates. Adjust based on the specific material’s requirements. Web sublimation heat press settings. Web getting the heat press time, temperature, and pressure parameters precisely right is crucial for ensuring a deep, lasting ink transfer that brings images to life. Web this comprehensive time and. Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following. So let’s talk about common sublimation heat press settings and how to determine times, temperatures, and pressures for different materials. Web a lower heat press temperature can seem like a safe starting point, but can produce light colors. Producing quality end products. Set the heat press to 380°f (193°c) for most substrates; Producing quality end products is a matter of suitable substrates, a calibrated heat press, smart color management, following. Web refer to our sublimation heat press settings chart for information on press time for different substrates. The following chart should serve only as a starting place. Web need a quick and. The following chart should serve only as a starting place. Web a lower heat press temperature can seem like a safe starting point, but can produce light colors. Web refer to our sublimation heat press settings chart for information on press time for different substrates. Set the heat press to 380°f (193°c) for most substrates; These sublimation cheat sheets give. These sublimation cheat sheets give you the answers, plus offer tips and tricks for getting your sublimation transfer right the first time. Web a lower heat press temperature can seem like a safe starting point, but can produce light colors. The following chart should serve only as a starting place. Web this comprehensive time and temperature chart serves as a. What temperature do you sublimate 100% polyester? The following chart should serve only as a starting place. Your settings will define the durability of your product. So let’s talk about common sublimation heat press settings and how to determine times, temperatures, and pressures for different materials. The print may crack or peel off from the substrate without the perfect settings. The print may crack or peel off from the substrate without the perfect settings. The following chart should serve only as a starting place. The following chart should serve only as a starting place. What temperature do you sublimate 100% polyester? Web refer to our sublimation heat press settings chart for information on press time for different substrates. So let’s talk about common sublimation heat press settings and how to determine times, temperatures, and pressures for different materials. Web this comprehensive time and temperature chart serves as a foundational resource for sublimation practitioners, offering precise recommendations for achieving optimal transfer results across a diverse range of substrates. Web getting the heat press time, temperature, and pressure parameters precisely right is crucial for ensuring a deep, lasting ink transfer that brings images to life. The following chart should serve only as a starting place. Web sublimation heat press settings. The following chart should serve only as a starting place. What temperature do you sublimate 100% polyester? Higher temperatures can overcook your sublimation prints. Set the heat press to 380°f (193°c) for most substrates; The correct temperature will ideally let the ink bond with your substrate, reducing the chances of damage. Web a lower heat press temperature can seem like a safe starting point, but can produce light colors. This comprehensive guide covers the ideal settings to. Your settings will define the durability of your product. Web refer to our sublimation heat press settings chart for information on press time for different substrates. These sublimation cheat sheets give you the answers, plus offer tips and tricks for getting your sublimation transfer right the first time. Web sublimation heat press settings.Sublimation Printable Heat Press Temperature Guide

Sublimation Heat Press Temperature Chart

Heat Press Temperature Sublimation Temperature Chart

Sublimation Time And Temp Chart

Sublimation Temperature Guide Cheat Sheet Temperature Etsy

Sublimation Heat Press Temperature Chart

Sublimation temperature and time chart

Sublimation Temperature Guide, Cheat Sheet, Temperature Chart, Easy

Sublimation Printable Heat Press Temperature Guide

Sublimation Temperature Guide Cheat Sheet Temperature Etsy

Producing Quality End Products Is A Matter Of Suitable Substrates, A Calibrated Heat Press, Smart Color Management, Following.

Web Need A Quick And Easy Way To Know The Time, Temperature, And Pressure Settings For Popular Sublimation Blanks?

The Following Chart Should Serve Only As A Starting Place.

Producing Quality End Products Is A Matter Of Suitable Substrates, A Calibrated Heat Press, Smart Color Management, Following Manufacturer Guidelines, Testing And Practice!

Related Post: