Galvanic Chart Corrosion

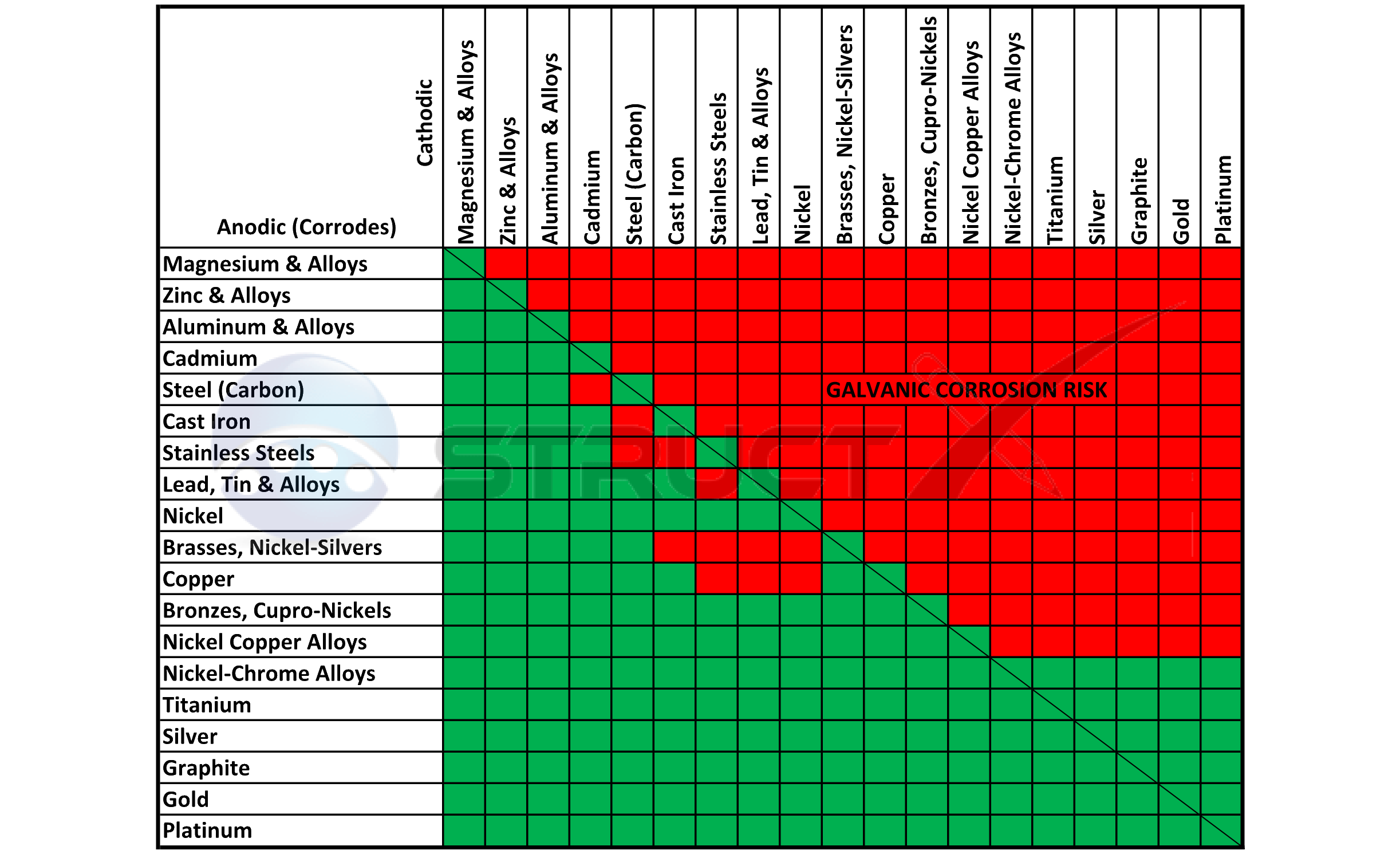

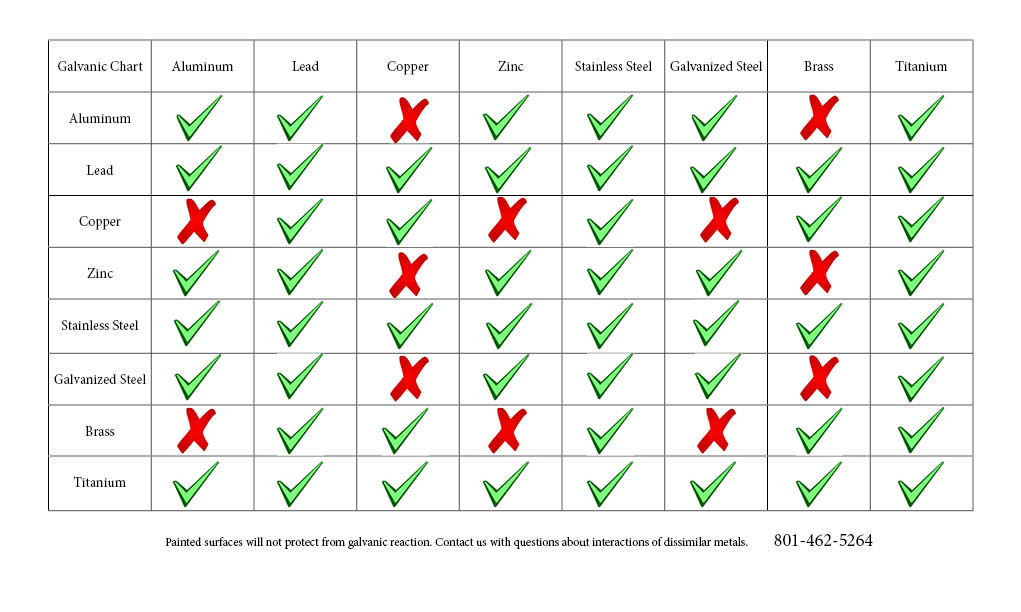

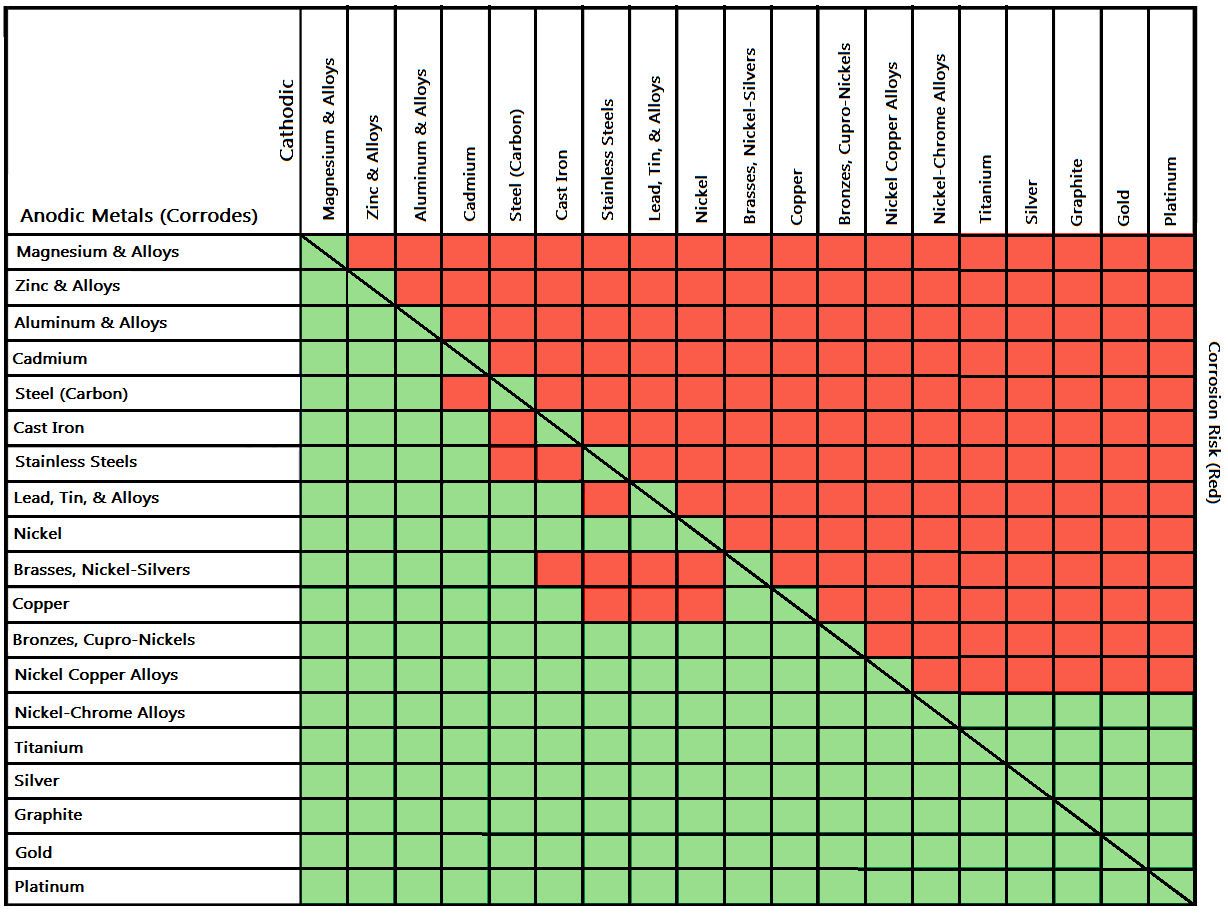

Galvanic Chart Corrosion - A similar galvanic reaction is exploited in primary cells to generate a useful electrical voltage to power portable devices. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal. The closer together the material are on the chart to the right, the less. However, understanding how it works and the steps that can be taken to protect against. We consider two metals compatible if their emf. Web below is a galvanic reaction chart for dissimilar metals. Web typically, the presence of an electrolyte (eg. Web galvanic corrosion is of particular concern in design and material selection. Web galvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. Web the increased corrosion of the anode is called “galvanic corrosion.” galvanic corrosion is sometimes used to extend the life of materials (i.e. However, understanding how it works and the steps that can be taken to protect against. Material selection is important because different metals come into contact with each other and. This phenomenon is named after italian ph… The below galvanic corrion chart or anodic index table shows anodic index for different materials. We consider two metals compatible if their emf. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates. Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. This can help you in the selection of the best. Web there are four elements necessary for corrosion to occur in a galvanic cell: Web the metal with the higher potential forms the anode and is corroded. We consider two metals compatible if their emf. A similar galvanic reaction is exploited in primary cells to generate a useful electrical voltage to power portable devices. Web below is the galvanic corrosion chart, along with steps for using the chart properly to determine metal compatibility. Galvanic. Web when corrosion does occur, the anodic material is the most likely to corrode, whereas the cathodic material is the least likely to corrode. Web galvanic corrosion is of particular concern in design and material selection. However, understanding how it works and the steps that can be taken to protect against. This can help you in the selection of the. The closer together the material are on the chart to the right, the less. Web galvanic corrosion is of particular concern in design and material selection. Web typically, the presence of an electrolyte (eg. This can help you in the selection of the best. Water) is necessary to promote galvanic corrosion. Web the increased corrosion of the anode is called “galvanic corrosion.” galvanic corrosion is sometimes used to extend the life of materials (i.e. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. Web galvanic corrosion is of particular concern in design and material selection. Web below is the galvanic. Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. Web there are four elements necessary for corrosion to occur in a galvanic cell: This phenomenon is named after italian ph… Zinc coatings on carbon. The most active metals in the galvanic corrosion chart, like aluminum, zinc, or. Web galvanic corrosion is of particular concern in design and material selection. Web below is a galvanic reaction chart for dissimilar metals. A similar galvanic reaction is exploited in primary cells to generate a useful electrical voltage to power portable devices. Web the galvanic corrosion table ranks. This can help you in the selection of the best. We consider two metals compatible if their emf. However, understanding how it works and the steps that can be taken to protect against. Web below is a galvanic reaction chart for dissimilar metals. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a. A typical rule of thumb is that. Web when corrosion does occur, the anodic material is the most likely to corrode, whereas the cathodic material is the least likely to corrode. However, understanding how it works and the steps that can be taken to protect against. Web there are four elements necessary for corrosion to occur in a galvanic cell:. The most active metals in the galvanic corrosion chart, like aluminum, zinc, or. The larger the separation distance in the electromotive chart between the two metals in contact, the. Web galvanic corrosion is of particular concern in design and material selection. We consider two metals compatible if their emf. Web the increased corrosion of the anode is called “galvanic corrosion.”. Web below is the galvanic corrosion chart, along with steps for using the chart properly to determine metal compatibility. Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates. Fastened of galvanic corrosion in joint, it’s. Zinc coatings on carbon steel and. This chart is designed to assist in broadly assessing the risk of galvanic. Web the increased corrosion of the anode is called “galvanic corrosion.” galvanic corrosion is sometimes used to extend the life of materials (i.e. This can help you in the selection of the best. Zinc coatings on carbon steel and. Material selection is important because different metals come into contact with each other and. Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Web below is the galvanic corrosion chart, along with steps for using the chart properly to determine metal compatibility. Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates. Web by knowing the relationships of the metals in the series, galvanic compatibility can be determined, preventing the possible harmful effects of galvanic. This phenomenon is named after italian ph… Web the galvanic corrosion table ranks metals from the most “active” to the least active. The most active metals in the galvanic corrosion chart, like aluminum, zinc, or. Web below is a galvanic reaction chart for dissimilar metals. Water) is necessary to promote galvanic corrosion. The closer together the material are on the chart to the right, the less. Fastened of galvanic corrosion in joint, it’s. Web the galvanic series chart below shows metals and their electrochemical voltage range (relative activity in flowing sea water).Galvanic Corrosion Chart Metals

Galvanic Corrosion Chart

Galvanic Corrosion Chart PDF Corrosion Electrochemistry

Galvanic Corrosion SSINA

GALVANICCORROSIONTABLE CMP Products Limited

Galvanic Corrosion Common Questions Answered

Galvanic Corrosion [with Chart] EngineerExcel

Galvanic Action Corrosion Prevention Architect's Blog

Galvanic Corrosion CMP Products Limited

Galvanic Series (electrochemical series)

A Typical Rule Of Thumb Is That.

Web When Corrosion Does Occur, The Anodic Material Is The Most Likely To Corrode, Whereas The Cathodic Material Is The Least Likely To Corrode.

Electric Current Flows From Plus To Minus.

Web The Metal With The Higher Potential Forms The Anode And Is Corroded.

Related Post:

![Galvanic Corrosion [with Chart] EngineerExcel](https://engineerexcel.com/wp-content/uploads/2023/03/galvanic-corrosion-chart.png)