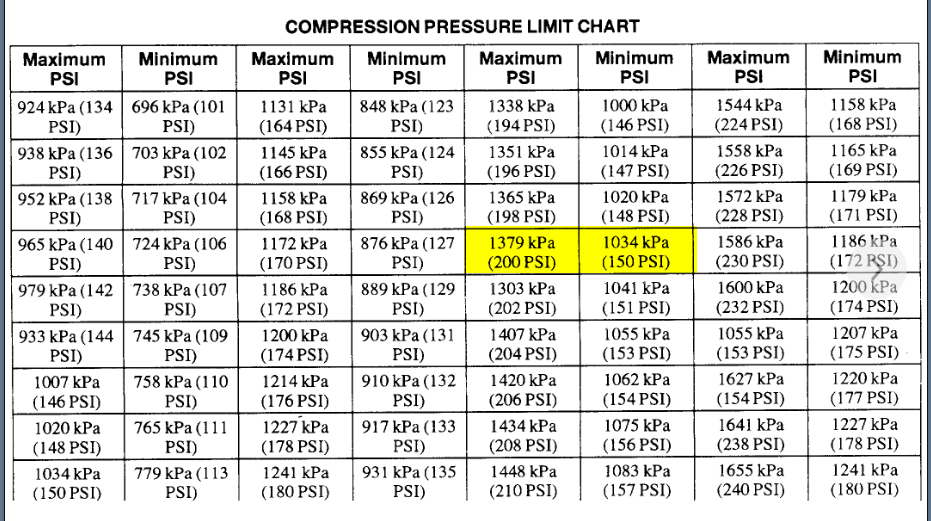

Engine Compression Test Chart

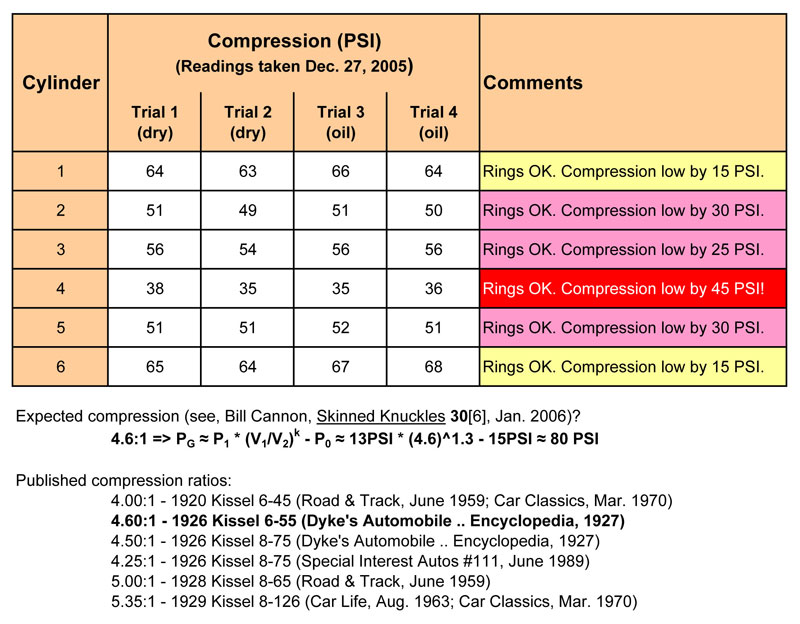

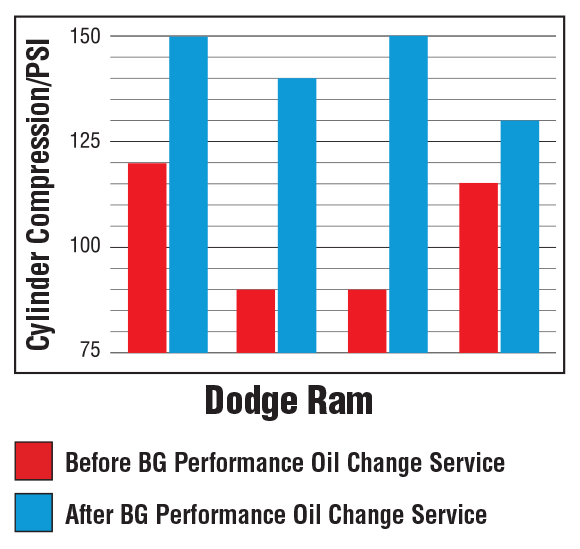

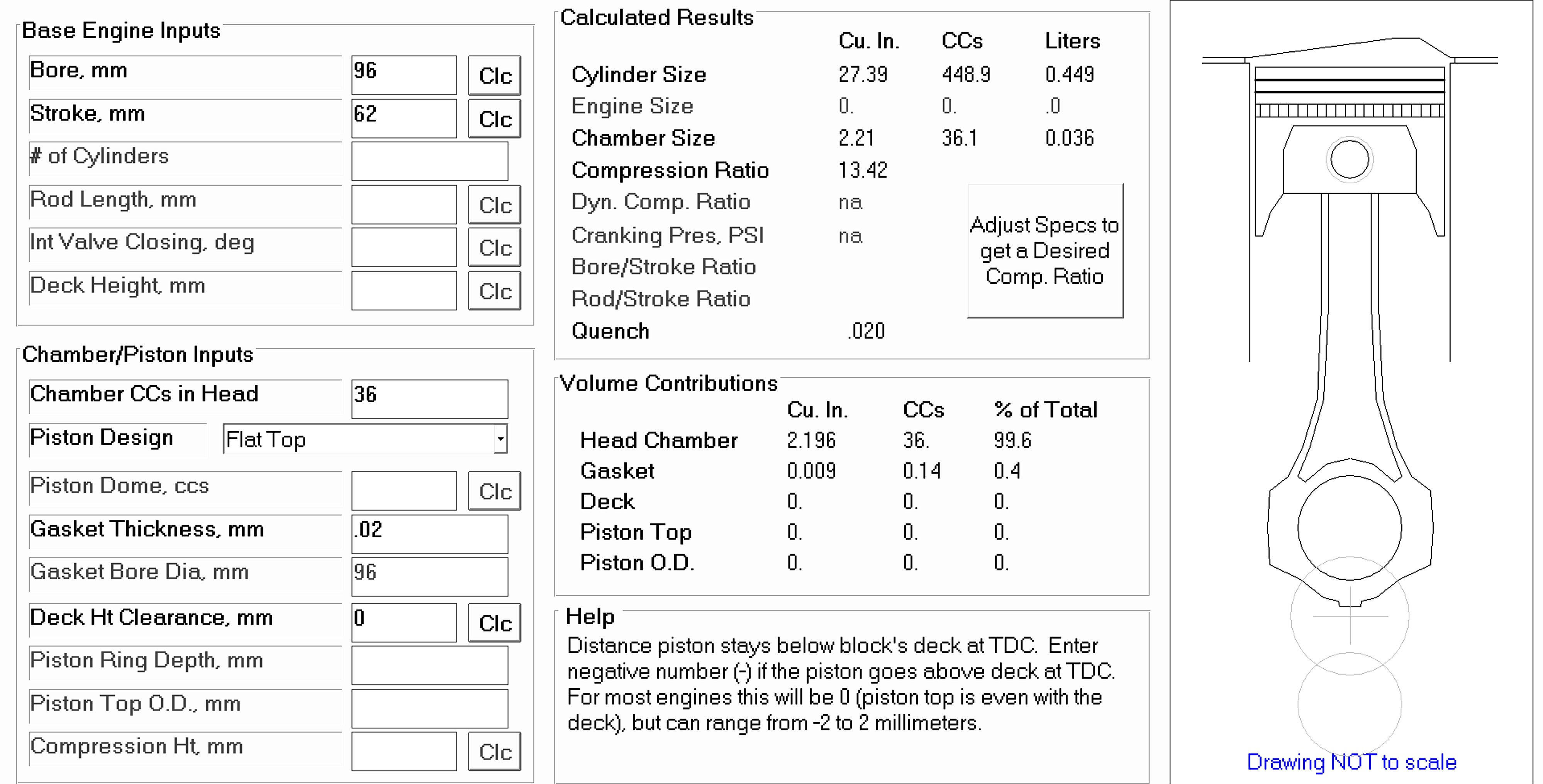

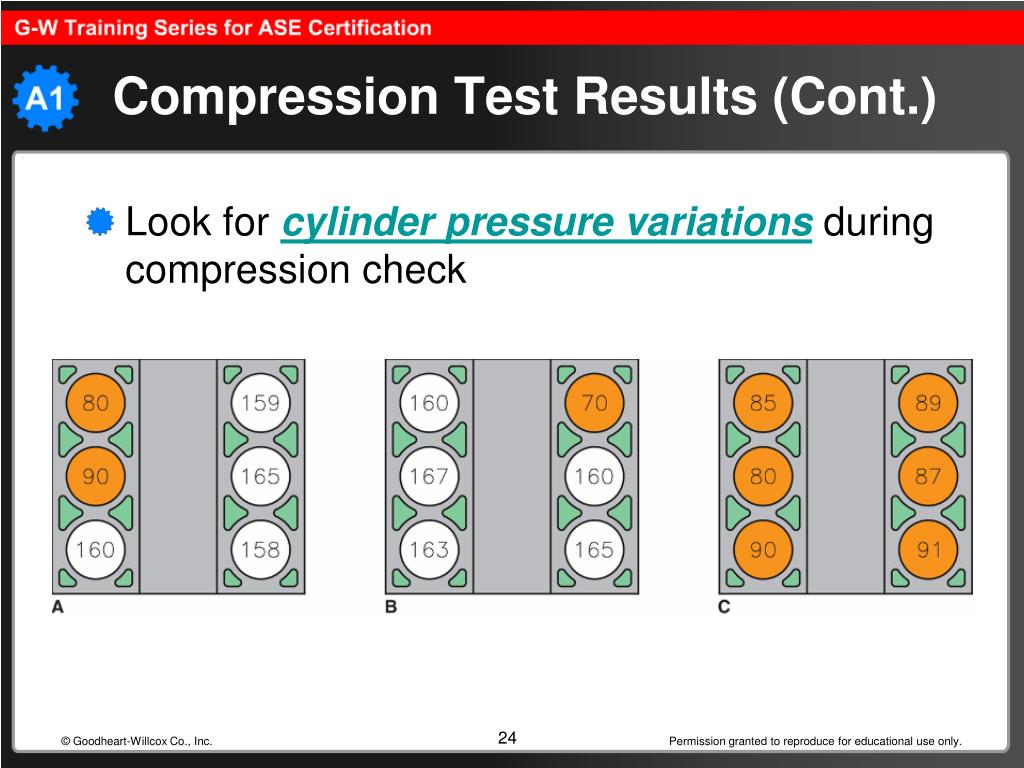

Engine Compression Test Chart - Look down on the engine to figure out which cylinder is closest to the front of the engine. Start with a cranking (static) compression test on a warm engine, to cancel out obvious problems, such as: Web the pressure of each cylinder should be measured and compared to the values for each of the remaining engine cylinders. Healthy engines should have compression. Web below is a guide on how to do a compression test and interpret the results. Web so, if your engine is running rough or is lacking power, consider doing a compression test. Remember that no engine is perfectly sealed. The first cylinder is on the rightmost ones in most engines. Disable the fuel pump relay, remove spark plugs, and maintain a clean workspace. Cooley shows you how to do the king of all engine tests. Web a compression test reveals the condition of your engine's valves, its valve seats, and piston rings and whether these parts are wearing evenly. Web narrow down on your goal compression ratio while being a quick and easy way to test different engine internal setups. Specifically, parts like intake and exhaust valves, valve seats, head gaskets, and the piston rings are common parts that can wear out and lead to. For example, consider a v6 with the following compression test results Web the premise of a compression test is to test each cylinder to see in measured psi exactly how much compression that particular cylinder is producing. Most engines will have a compression ratio that exceeds 100 psi. Low engine compression can cause a misfire code. Web by measuring the compression pressure generated within each cylinder, technicians can identify potential issues such as worn piston rings, leaking valves, or damaged cylinder walls, enabling them to address these problems promptly and restore optimal engine performance. Because, we will compare results, between cylinders to determine what it all means. Web below is a guide on how to do a compression test and interpret the results. Web the premise of a compression test is to test each cylinder to see in measured psi exactly how much compression that particular cylinder is producing. Web by measuring the compression pressure generated within each cylinder, technicians can identify potential issues such as worn piston rings, leaking valves, or damaged cylinder walls, enabling them to address these problems promptly and. Cooley shows you how to do the king of all engine tests. Analysis of the current/voltage changes gives the comparative compression values of all cylinders. Note the circular cylinders and the timing belt on the engine’s front. No cylinder should have a pressure lower than 75% of the highest recorded value. Web create a chart similar to this example to. Attach the gauge to each cylinder, ensuring a secure connection. Healthy engines should have compression. Web the principle of the relative compression test is based on tracking the battery current/voltage changes during cranking to determine the compression values of all cylinders. Put the compression test adapter into the engine's first cylinder. Web testing engine compression provides a snapshot of the. Web create a chart similar to this example to record your test readings. Begin with a normal (static) compression test on a warm engine to eliminate obvious problems such as badly worn rings, burnt or bent valves or holes in pistons. Web below is a guide on how to do a compression test and interpret the results. Web a compression. No cylinder should have a pressure lower than 75% of the highest recorded value. Because, we will compare results, between cylinders to determine what it all means. Remember that no engine is perfectly sealed. The test will help you locate potential internal problems affecting engine performance. Cooley shows you how to do the king of all engine tests. Low engine compression can cause a misfire code. Web a compression test is to determine how much pressure the engine makes, and a leakdown test measures its ability to hold pressure. Web a compression test is a decent way to assess the sealing functions of an engine’s valves and valve seats, piston rings and cylinder head gaskets. Web the premise. Engine compression atmospheric pressure at. Click here and try our compression calculator now! Crank the engine and note stable pressure levels. Web to check your vehicle’s engine with a compression test, you need a compression gauge and safety gear. Analysis of the current/voltage changes gives the comparative compression values of all cylinders. Look down on the engine to figure out which cylinder is closest to the front of the engine. Web below is a guide on how to do a compression test and interpret the results. Note the circular cylinders and the timing belt on the engine’s front. Web a compression test is a decent way to assess the sealing functions of. Web the pressure of each cylinder should be measured and compared to the values for each of the remaining engine cylinders. Web below is a guide on how to do a compression test and interpret the results. Web so, if your engine is running rough or is lacking power, consider doing a compression test. Web a compression test is to. Web narrow down on your goal compression ratio while being a quick and easy way to test different engine internal setups. For example, consider a v6 with the following compression test results Web a compression test reveals the condition of your engine's valves, its valve seats, and piston rings and whether these parts are wearing evenly. Disable the fuel pump. Web an engine compression test is the most practical way to learn about the mechanical condition of your engine without the need to disassemble it. Specifically, parts like intake and exhaust valves, valve seats, head gaskets, and the piston rings are common parts that can wear out and lead to. The first cylinder is on the rightmost ones in most engines. Remember that no engine is perfectly sealed. No cylinder should have a pressure lower than 75% of the highest recorded value. Begin with a normal (static) compression test on a warm engine to eliminate obvious problems such as badly worn rings, burnt or bent valves or holes in pistons. Web the pressure of each cylinder should be measured and compared to the values for each of the remaining engine cylinders. Web then, use this chart to record all the compression information, from the cranking (static), idle and snap tests. How to prepare for a compression test. Web by measuring the compression pressure generated within each cylinder, technicians can identify potential issues such as worn piston rings, leaking valves, or damaged cylinder walls, enabling them to address these problems promptly and restore optimal engine performance. In this video, we show you how to do it and how to interpret the results. Web how to do a compression test on your engine. The test will help you locate potential internal problems affecting engine performance. 705k views 7 years ago. Crank the engine and note stable pressure levels. Engine compression atmospheric pressure at.Engine Compression Test Chart

Engine Compression Test Chart

StepbyStep Guide to Do a Car Engine Compression Test

Compression test procedure?

Engine Compression Chart

Engine Compression Test A Crucial Diagnostic Tool for Your Vehicle

Repair Guides Engine Mechanical Checking Engine Compression

PPT Engine Problem Diagnosis and TuneUp PowerPoint Presentation

Engine Compression Test Chart

Engine Compression Test Chart

Put The Compression Test Adapter Into The Engine's First Cylinder.

Web How To Do An Engine Compression Test On 3.0L And 3.8L V6 Equipped Ford, Mercury And Lincoln.

Most Engines Will Have A Compression Ratio That Exceeds 100 Psi.

Look Down On The Engine To Figure Out Which Cylinder Is Closest To The Front Of The Engine.

Related Post: