Allen Bradley Overload Chart

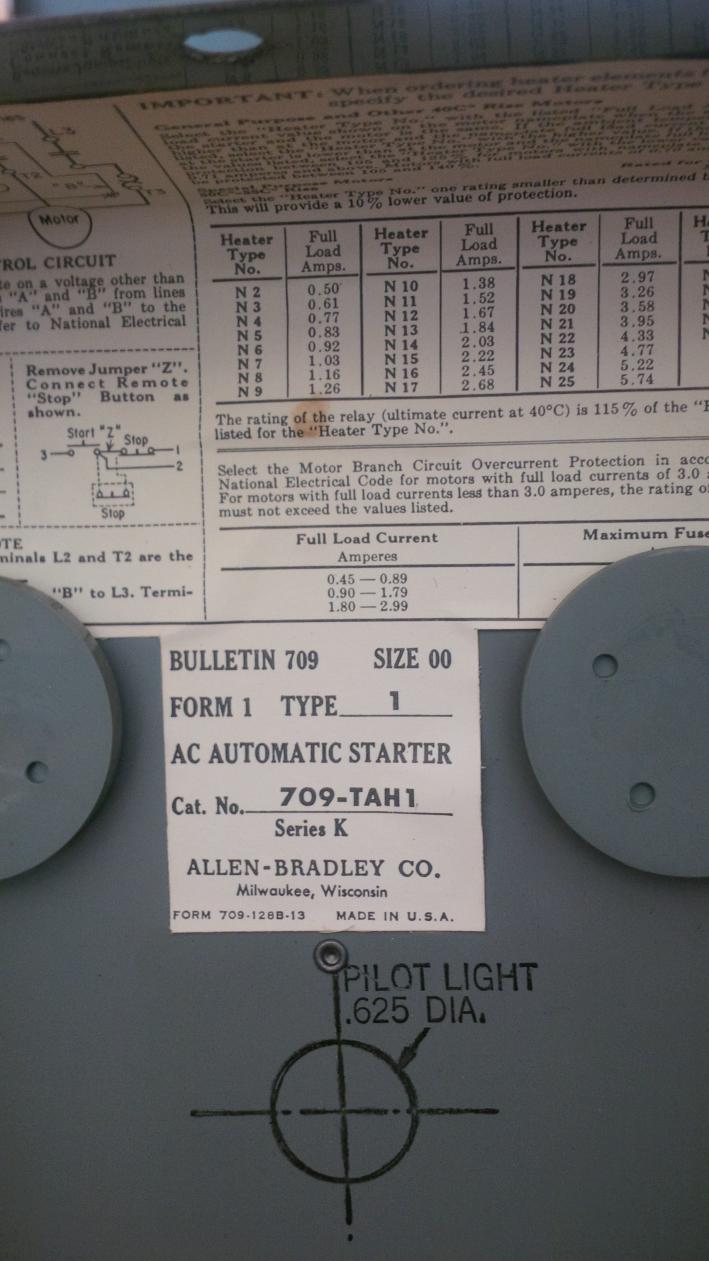

Allen Bradley Overload Chart - Web e300/e200 electronic overload relays. So if you have something different than that you need to make the adjustments yourself, to arrive at the proper size. Specific applications may require class 10 or class 30 overload relays. The old style type n heater elements are used with bulletin 709. For nema size 2 motor starter only. Three modules comprise the e300 relay. These starters meet nema standards, are easy to wire and service, simple to select, and offer class 10, 15, 20, and 30 overload protection in the complete range of nema sizes 00 to 9. These relays include enhanced features to better safeguard your motor protection investments. *control parts is not a rockwell automation authorized distributor or in any way affiliated with rockwell automation*. Elow for a particular motor. Web most nema designed overload relays, heater elements and charts, are set up for 1.15sf motors, which have been the norm for industrial motors for years now. Selection of heater elements for overload relays. The modular design, communication options, diagnostic information, simplified wiring, and integration into logix technology make them the ideal overload for. Web allen bradley, w series, thermal overload heater element, type w, suitable for use with thermal overload relays to protect your motor. These relays include enhanced features to better safeguard your motor protection investments. Three modules comprise the e300 relay. These starters meet nema standards, are easy to wire and service, simple to select, and offer class 10, 15, 20, and 30 overload protection in the complete range of nema sizes 00 to 9. Its modular design, communication options, diagnostic information, simplified wiring, and integration into logix technology make this the ideal overload for motor control applications in an automation system. This provides class 20 operation and is recommended for general applications. Web e300/e200 electronic overload relays. Selection of heater elements for overload relays. This provides class 20 operation and is recommended for general applications. The device is split between two offerings: These relays include enhanced features to better safeguard your motor protection investments. Full load amp max ranges from 13.7 to 36.9 depending on model. This provides class 20 operation and is recommended for general applications. Web overload relay heater tables. Web most nema designed overload relays, heater elements and charts, are set up for 1.15sf motors, which have been the norm for industrial motors for years now. The modular design, communication options, diagnostic information, simplified wiring, and integration into logix technology make them the. The old style type n heater elements are used with bulletin 709. *control parts is not a rockwell automation authorized distributor or in any way affiliated with rockwell automation*. Three modules comprise the e300 relay. Web this chapter provides instructions about how to operate and configure an e100tm electronic overload relay system. Its modular design, communication options, diagnostic information, simplified. This provides class 20 operation and is recommended for general applications. Web the e300/e200 electronic overload relay is the newest technology for overload protection. So if you have something different than that you need to make the adjustments yourself, to arrive at the proper size. These starters meet nema standards, are easy to wire and service, simple to select, and. Selection of heater elements for overload relays. Its modular design, communication options, diagnostic information, simplified wiring, and integration into logix technology make this the ideal overload for motor control applications in an automation system. Learn how to avoid the risks of unauthorized and counterfeit products. So if you have something different than that you need to make the adjustments yourself,. Specific applications may require class 10 or class 30 overload relays. The device is split between two offerings: This provides class 20 operation and is recommended for general applications. It includes instructions about how to set the trip current and trip class. Web this chapter provides instructions about how to operate and configure an e100tm electronic overload relay system. *control parts is not a rockwell automation authorized distributor or in any way affiliated with rockwell automation*. Web nema overload relay heater element. Web allen bradley, w series, thermal overload heater element, type w, suitable for use with thermal overload relays to protect your motor. The modular design, communication options, diagnostic information, simplified wiring, and integration into logix technology make. So if you have something different than that you need to make the adjustments yourself, to arrive at the proper size. Web allen bradley overload relay heater tables for bulletin 709 & 509. The device is split between two offerings: Selection of heater elements for overload relays. For nema size 2 motor starter only. Web bulletin 509 starters are designed for full voltage voltage starting of polyphase squirrel cage motors. Web allen bradley overload relay heater tables for bulletin 709 & 509. The device is split between two offerings: This provides class 20 operation and is recommended for general applications. Specific applications may require class 10 or class 30 overload relays. *control parts is not a rockwell automation authorized distributor or in any way affiliated with rockwell automation*. — allen bradley motor starter thermal overload heater units. Learn how to avoid the risks of unauthorized and counterfeit products. Web allen bradley overload relay heater tables for bulletin 709 & 509. Web overload relay heater tables. Learn how to avoid the risks of unauthorized and counterfeit products. Web nema overload relay heater element. Web allen bradley, w series, thermal overload heater element, type w, suitable for use with thermal overload relays to protect your motor. Class 10 overload relays are often used with hermetic Specific applications may require class 10 or class 30 overload relays. Specific applications may require class 10 or class 30 overload relays. Login to see your account pricing. Web this chapter explains how to assemble the three module types of the e300 electronic overload relay, wire the relay, and set the relay ip address. Selection of heater elements for overload relays. Web overload relay heater tables. These starters meet nema standards, are easy to wire and service, simple to select, and offer class 10, 15, 20, and 30 overload protection in the complete range of nema sizes 00 to 9. Web bulletin 509 starters are designed for full voltage voltage starting of polyphase squirrel cage motors. Web this chapter provides instructions about how to operate and configure an e100tm electronic overload relay system. Web most nema designed overload relays, heater elements and charts, are set up for 1.15sf motors, which have been the norm for industrial motors for years now. The device is split between two offerings: Three modules comprise the e300 relay.Allen Bradley Heater Chart

Allen Bradley Overload Heater Chart Type W Chart Walls

Overload Heater Size Chart

Allen Bradley Overload Heater Chart

Allen Bradley Thermal Overload Chart

Allen Bradley Overload Chart Pdf treerr

allen bradley motor starter overload chart Celesta Fischer

allen bradley motor starter overload chart Celesta Fischer

allen bradley motor starter overload chart Celesta Fischer

Allen Bradley Overload Chart

Motor Amps Higher Or Lower Than The Values Listed Will Vary Depending On The Type And.

Web Allen Bradley Overload Relay Heater Tables For Bulletin 709 & 509.

For Nema Size 2 Motor Starter Only.

*Control Parts Is Not A Rockwell Automation Authorized Distributor Or In Any Way Affiliated With Rockwell Automation*.

Related Post: